Sister’s Cancer Inspires Blacksmith to Make Smokeless Chulha That Saves 60% Fuel

Manipur-based Maidem Deben Singh’s innovative biomass smokeless stove can cook and dry meat and vegetables, saving hundreds of lives

Every year news that Northern India is choked with air pollution caused by poisonous gases emitting from vehicles and stubble burning by farmers makes headlines. But the situation in the far Northeast is no different.

According to a Lancet report, about 56 per cent of the population in the Northeastern states suffer from chronic diseases caused by the burning of solid fuels — the highest in India.

But for Maidem Deben Singh, a native of Imphal, this was not limited to just reading a fact in an international research journal. The effects of the harmful smoke emitting from coal while cooking led to his sister being diagnosed with lung cancer.

Learning of his sister’s disease had a life-changing impact on Deben. It was then that he decided to become an innovator and prevent others from inhaling harmful gases emitted from the chulha (traditional stove).

Eco-Friendly, Cost-Effective Stove

A Class 7 dropout, Deben followed in his father’s footsteps to work as a jeep driver with the State Government Department. Deben could not pursue education owing to his family’s financial condition. In the early 1970s, he joined the profession and worked for nearly three decades. But the commute to his job and his hectic lifestyle forced him to quit. He also worked as a labourer at construction sites around 2005 and then to reduce physical labour, he became a blacksmith.

But it was in 2011 that he learned about the health issues of his sister. “I learned from the doctors treating my sister about how smoke from a traditional stove causes lung cancer. I felt terrible and decided to find a solution to the problem. Like my sister, many women were suffering from the same,” he says.

Around 2012 Deben decided to use his smithing skills in building a stove that emits less smoke.

Deben struggled for months to make a stove using aluminium and steel sheets and welding material. “I had a challenging time creating the inner chambers and channelising the heat in required directions. Eventually, I succeeded. Not only was it smokeless, but the stove also reduced the fuel requirement offering health and monetary benefits to the user,” he says.

The 70-year-old adds, “I built a prototype in a secluded place without letting others know. Once it was ready, I informed my son, Thoithoi. A year later, we named it Emionu stove and displayed it in an Innovation Exhibition organised by the Central Government at the Rashtrapati Bhavan, Delhi.”

However, while demonstrating it to the visitors, Deben faced an unexpected issue. “The stove was mounted on a plastic table, and the heat from the bottom started melting the material. I did not expect the stove to generate heavy heat. That’s how I eventually supported my stove using wood,” he recalls.

But this problem laid the foundation for another unique solution. Learning that the bottom of his stove generates significant heat, Deben decided to channelise it to dry fish and vegetables. “Dry fish is consumed in large amounts in Manipur, and drying it at home instead of buying the same could save people money,” he says.

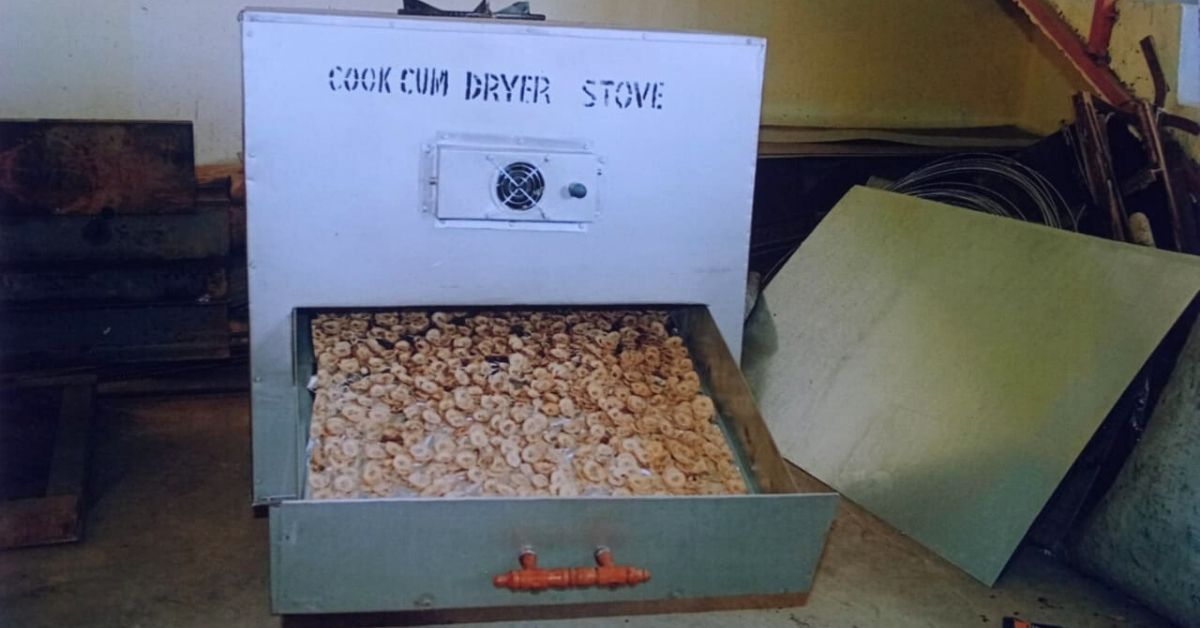

With minor modifications in his original design, Deben added trays at the bottom. “The upper part of the stove has burners, which is used for cooking vegetables and meat, while the bottom trays use the excess heat to dehydrate and dry the vegetables and fish,” he explains.

Deben says that the drying trays work effectively and do not burn the fish or vegetables. “The food can be preserved for a longer duration and consumed when needed,” he says.

Explaining further, he says, “It requires about 30 minutes to boil 10 litres of water using an LPG cylinder. But the same job is done by the biomass stove in 15 to 17 minutes.”

Deben says that the fuel requirement of his stove is far lesser than compared with traditional stoves. “A chulha requires about 500 gm of charcoal to boil 10 litres of water, but my stove requires about 150-200 gm. It saves about 60 per cent of fuel. Moreover, it emits about 90 per cent less smoke compared to the conventional stoves,” he notes.

Besides charcoal, biomass like wood and agricultural waste can also be used as fuel. Efficient fuel burning does not blacken the utensils due to inefficient carbon burning at the bottom.

The National Innovation Foundation (NIF) took cognisance of his work and awarded him for his innovative idea. “I had no information about the award and never expected it. My son applied for it, and a team of scientists and experts visited us to inspect my innovation. Researchers from IIT Manipur even studied my innovation and concluded it to be 10 per cent efficient as compared to the conventional stove. They suggested some modifications to make it user-friendly. After feeling convinced with the product’s utility, the jury nominated my innovation for the award. The government conferred me during the 9th National Biennial Grassroots Innovation and Outstanding Traditional Award 2017 at the hands of the then President Pranab Mukherjee,” he says.

After the award, Deben received support from the Government of Manipur, who allowed him a permanent shed in an industrial area. The NIF also extended a helping hand by offering a business development grant under the Micro Venture Innovation Fund (MVIG) to scale its production. The foundation also acquired the Emoinu stove under its Grassroots Technological Innovation Acquisition Fund (GTIAF) for promoting the product to a wider market.

That’s when Deben decided to commercialise his product with the brand Kangleipak Fish Dryer (KFD). “Locals address Manipur by its old name ‘Kangleipak’. So, I decided to use that name to relate to my customers,” he says.

Since then, Deben has sold over 150 units of his innovation. “I earn Rs 30,000 from selling the biomass-fuelled stove and dryer,” he adds.

Towards A Healthier Life

Rahul Naorem, an entrepreneur and Deben’s recent customer, says, “I learnt about the cooking and drying stove on Facebook and approached Deben. I have been using the stove for the past six months at my restaurant, replacing the LPG cylinder.”

Rahul says he finds it convenient and economical to operate. “It also holds a multi-purpose value as multiple items can be cooked or dried simultaneously,” he adds.

Deben has also conceived different versions of his innovations such as a fish dryer, room heater, pork dryer, square punching machine. The other products include a multi(purpose)-chulha, a multi-diamond stove, fish scale remover machine. The products range between Rs 650 and Rs 20,000.

But the COVID-19 pandemic has put a spanner in his work. “The economic conditions and less interaction with customers have resulted in lesser sales. Moreover, the State Government’s newer laws discourage woodcutting, leading to a shortage of charcoal. Using biomass as fuel also limits the products to rural consumers as urban dwellers prefer LPG,” Thoithoi says.

Thoithoi, who helps his father with marketing the products, adds, “Currently, we are modifying the stove and making it operable by electricity. The switch will also enable it to tap urban and semi-urban markets. A few more products are also underway and will be launched soon.”

Deben says that he wants more villagers to adopt his stove to living a healthy lifestyle. “I have succeeded in my cause to work towards reducing environmental pollution and hope my son continues the legacy for years to come,” he adds.

Source: Lancet report

Edited by Yoshita Rao

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let’s ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?

This story made me

-

97

-

121

-

89

-

167