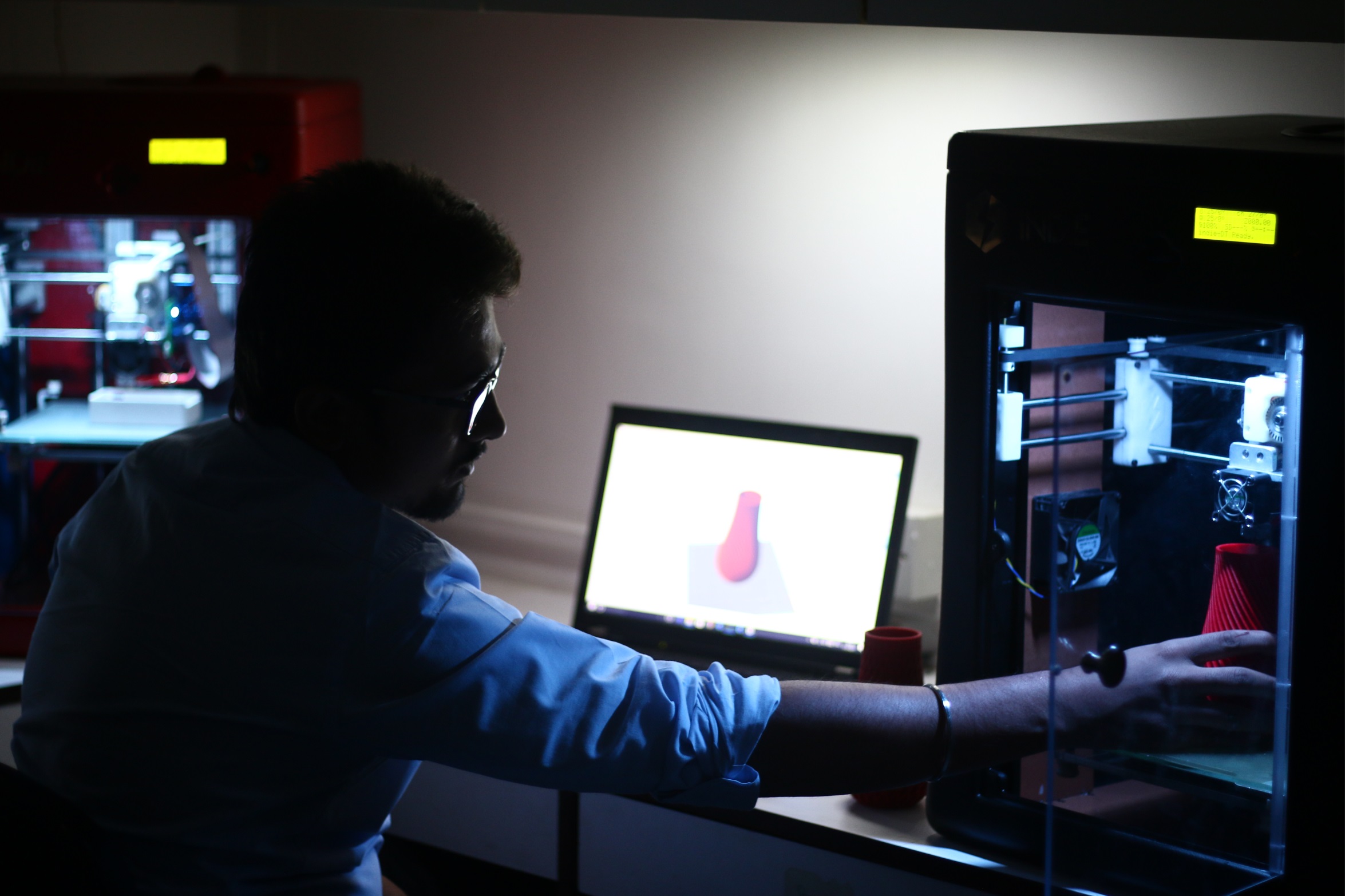

This Made-In-India 3D Printer Can Revolutionize the Affordable Tech Space in India!

Indie 3D Printer has been created by Maher Soft, a tech startup operating in Mumbai, which has priced the open source technology based device at Rs 37,000.

While some of us are still struggling with our regular printers, much of the world has moved on to the phenomenon of 3D printing. Since the 1980s when it first emerged in the spotlight, 3D printing has gained in popularity for its capacity to showcase designs in a three-dimensional manner. American economist and social theorist Jeremy Rifkin has even called it the start of a third Industrial Revolution.

Seeking to make these next-gen devices more accessible and affordable, tech startup Maher Soft has created Indie, a made-in-India 3D printer.

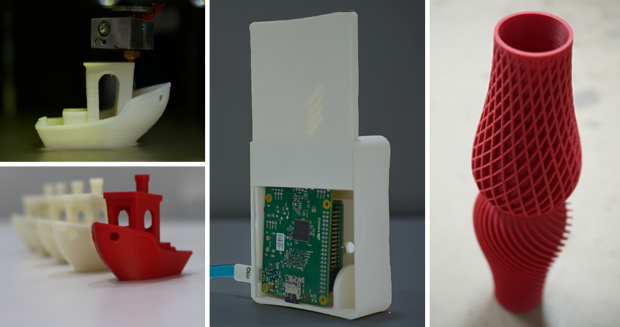

As many a design or tech geek will excitedly confirm, 3D printers are almost magical in the capacity to swiftly create an object from its design using the machine. Think crockery, miniature animals, jewellery—while industries can use it to create prototypes, personal 3D printers can bring about a complete transformation in creativity and consumption.

Maher Soft, the company behind Indie, is a 3D Printer manufacturer and service company based in Mumbai, and believes in making technology simple and accessible. Karan Sangani, the company’s chief sales officer says, “Building 3D printers is easy. Building reliable 3D printers is definitely not.”

You may also like: This Electrical Engineer and IIM Alumnus Is Now Helping Small Farmers with Her Innovations

The company’s frustrating experience with consumer-grade 3D printers led it to develop its own version, a compact and affordable device that can be used with the user’s desktop. “We are using a combination of industrial grade parts, conventional manufacturing techniques and 3D-printed parts to deliver superior value.”

3D printers are often limited due to exorbitant pricing, costing over a lakh for a quality model, and high maintenance requirements. The price tags make it virtually impossible for small businesses or students to invest in the machines.

Karan says, “3D printers available in the market are of poor quality, plus they are difficult to maintain. Furthermore, they are expensive. Our goal is simple: We want to bridge the part-quality and performance gap between Industrial and Desktop FDM 3D Printers. Our team has spent a year on Indie, designing each component to make it reliable and replicable by sourcing the right manufacturers in India and at the same time getting the moulds ready for production.”

Among Indie’s biggest advantages are its affordable pricing and low consumption of power.

A make-in-India approach has helped the Maher Soft team keep prices limited to Rs 37,000. “We redesigned the Indie from ground up, where the primary focus was that how can we get high quality 3D prints while using locally sourced components and manufacturing the product in India,” says Karan.

“We went through multiple iterations of the model, testing each component and worked with our vendors to reduce costs. We have also made injection moulds for certain components to reduce the part costs and are using composite materials that give the best weight to strength ratio.”

Indie printers are also integrated with open-source technology, so that users do not have to rely only on proprietary tools and solutions.

“We initially started building the most basic prototype with an idea to deliver to our customers a product that can print functional models at an affordable cost,” says Karan. The model has gone through 8-10 design iterations to its present state.

“Manufacturing a hardware product in India comes with lots of challenges, like getting access to right materials for manufacturing the printed circuit board, hardware components, machine body or machine packaging. We spent a lot of our time to find the right suppliers and vendors who helped us streamline the manufacturing and sourcing.”

You might also like: This Startup Aims to train 1 Lakh First Responders for Medical Emergencies in Every Indian City

The team is currently running a crowdfunding campaign to secure their production budgets. Karan says, “We are one of the very few tech startups from India taking the crowdfunding route to validate our product around the world. We have been able to raise $20,000 in just 15 days with backers from more than 10 countries. Crowdfunding is the most efficient and effective way to reach customers.”

You can contribute to Indie’s crowdfunding campaign here. To contact the Maher Soft team, click here.

Like this story? Or have something to share? Write to us: [email protected], or connect with us on Facebook and Twitter.

NEW: Click here to get positive news on WhatsApp!

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let’s ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?

This story made me

-

97

-

121

-

89

-

167