Bendable But Not Breakable: Hyderabad Scientists Develop Novel Smart Material!

This graphite-based material was developed by the science team from the University of Hyderabad, and can see its various applications in science and technology

One of the factors that helped technology to be where it is today is its compatibility with our lifestyle. Portable tech, wearables and inconspicuous design are the futuristic norms of technology.

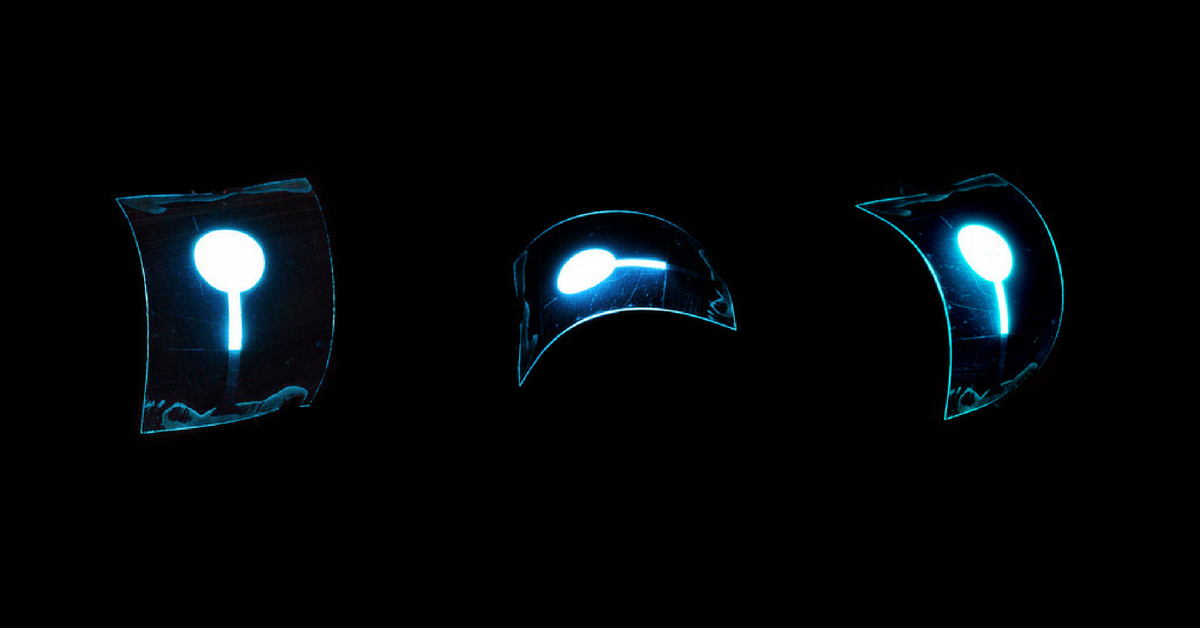

And the road to that future is paved by innovations like the one developed by scientists at the University of Hyderabad. They have fabricated a new composite material that can be bent, twisted and stretched without damage.

With multiple electronic applications, the material can easily be used for manufacturing electric switches, smartphones, computer keyboards, touch sensors, and even healthcare products.

This graphite-based material was developed by the science team from the University of Hyderabad, directed by Professor Raj Kishore Dash, a renowned researcher at the School of Engineering and Technology Sciences and his PhD student, Gunda Rajitha.

The scientists told Business Line, “We are very excited about this development. The very low optical transparent material can be used for the development of future transparent wearable sensors and biomedical devices.”

The material was achieved by incrustation of graphite, a very thin layer of carbon into a silicon-based organic polymer called Polydimethylsiloxane (PDMS).

The flexible composite material achieved 88% optical transparency and had a high dielectric constant, which means it could be used in micro-electromechanical systems (MEMS).

And since most of the MEMS and sensors generally require higher repeatability and reversible electromechanical response for higher performance and efficiency, highly flexible material is required. And this is where the newly fabricated material excels.

With a wide range of applications, the innovation has the potential to evolve to be compatible with various everyday tech and find its use in various fields, not limited to technology.

(Edited by Shruti Singhal)

Hey, you may also like: Hyderabad to Get India’s 1st Specialty Hospital to Tackle High-Risk Infections!

Like this story? Or have something to share?

Write to us: [email protected]

Connect with us on Facebook and Twitter.

NEW: Click here to get positive news on WhatsApp!

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let’s ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?

This story made me

-

97

-

121

-

89

-

167