Love for Sarees Inspires Sisters to Build Rs 50 Crore Brand; Empower 16,000 Weavers

With no background in the textile and apparel world, Sujata and Taniya Biswas left their cushy corporate jobs and started building Suta, which is empowering weavers and making beautiful sarees.

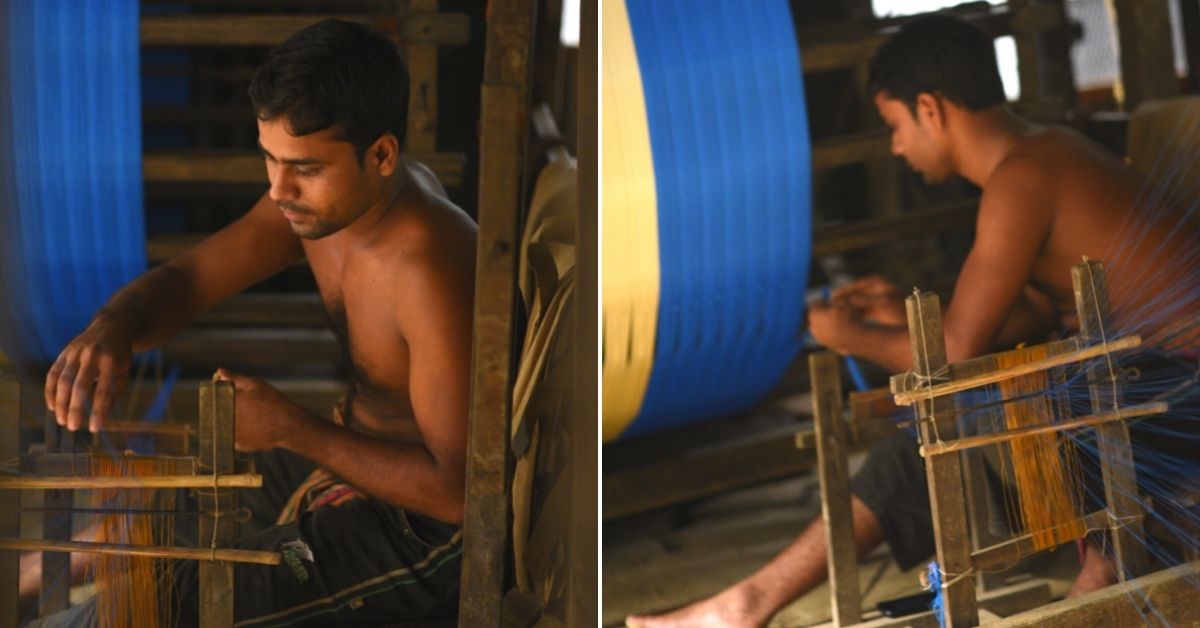

Sujata and Taniya Biswas gave up their cushy corporate careers on 1 April 2016 and dedicated themselves entirely to building a brand called Suta (meaning ‘thread’). Set on positively impacting weaver and artisan communities, they ensure that their traditional crafts thrive. Known primarily for their exquisite range of cotton sarees, in varieties of jamdani weave, mulmul, malkesh, banarasi, amongst others, Suta is a venture with a cause.

Learn How to Build Your Own Business From Scratch, From The Suta Sisters

“Our brand is largely known for its range of cotton sarees from different traditions, but we also work with the purest mulberry silk as well, handloom ikats and linen, amongst others. On silk and cotton, we employ techniques like hand batik, block-printing, embroidery, etc. Despite having no background in fashion or textiles, both of us felt a strong urge to start a brand that would positively impact the weaver and artisan community and revive the dying art forms of India. We have 16,000 weavers and artisans who work with us on a contractual basis and also provide employment to their family members,” says Sujata, speaking to The Better India.

What began as a passion project to “explore our creative curiosities and personal inspirations” has in nearly six years turned into a business that has generated about Rs 50 crore in revenue and created a “happy place” for over 150 full-time employees.

“Suta is an amalgamation of our collective desire to make a positive impact on-ground to ensure the legacies of our precious crafts and weaves find a place in the modern context,” says Taniya.

The brand has recently launched a line of men’s kurta and is soon getting into women’s kurtas. In addition, the venture is already into loungewear, home decor, handbags, jewellery, etc.

“We are getting into a lot of verticals, but we are known as a one-stop-shop for sarees. If you want to wear a saree today, you can just pick it up from one of our stores and wear it,” she adds.

Building Suta

The sisters grew up in a family that moved around different parts of the country given their father’s transferable job in the Indian Railways. Never living in one particular city for an extended period, they mostly grew up living in the eastern part of India, witnessing a lot of different cultures, cuisines, communities and sartorial choices. Their childhood was filled with memories of seeing the collection of sarees owned by their mother and grandmother.

“After earning my engineering degree and MBA, I worked in the branding and steel industry, following which I applied for a PhD at IIT-Bombay to study e-commerce businesses. It was around this time when Taniya and I began thinking about starting our venture,” recalls Sujata.

In 2013, Taniya too joined her sister in Mumbai, working for IBM as a consultant after her MBA from IIM-Lucknow. Although the sisters liked their respective jobs, they weren’t impacting lives as they wanted. After a year passed following Taniya’s move to Mumbai, they began working on building their venture while also doing their day jobs.

For the next two years, they were learning, committing mistakes, getting cheated and hunting for the right fabric and skilled weavers across different corners of India. Their search for skilled weavers took them to the remote corners of West Bengal, where they currently have their two factories — Shantipur in Nadia district, and Dhaniakhali; Madhya Pradesh; Meghalaya; Varanasi (home to the world-famous Banarasi sarees); Maniabandha in Odisha; and Kutch district in Gujarat, amongst other places. Visiting these locations further burnished their love for fabric.

“Upon travelling to these villages, our love for sarees also grew. People would often tell us that sarees were for special occasions or something that elderly women wore during visits to the temple, etc. We wanted to change that perception and bring sarees back to everyday life. We started with mulmul sarees, a fine, lightweight and soft cotton muslin. The first weavers we approached didn’t agree to make plain mulmul sarees without starch. This is because usually in rural West Bengal, for example, mulmul sarees are embroidered on and the plain ones, they said, were only worn by widows. There was not much of a market for plain mulmul sarees and only a few weavers were making it. We eventually found those weavers,” recalls Sujata.

As Sujata adds, “We didn’t even give them any designs to work with initially. These were plain one-coloured sarees we were making. We wanted to launch these sarees because we wanted to bring them back into young people’s lives. We started selling these sarees for Rs 1,250 (with GST, Rs 1,313). We were doing all this while working full-time.”

“No matter the circumstances at work, I used to come back on the weekends. Whatever orders we would get, both of us spent the weekend packing and shipping them out. We did all of this ourselves and had no employees then. When we quit our jobs in 2016, we had one employee who would do the packing and labelling, and two weavers onboard who were working full-time with us. Before that we were working on and off on our venture, doing our shoots, figuring out the business model. We also organised a lot of exhibitions, endured many failures, figured out who our customers were and did all that in two years,” says Taniya.

Telling Stories

When they launched Suta, the sisters were prepared and invested about Rs 3 lakh each. They began their journey of making very basic sarees accessible to people.

The sisters were focused on making simple designs with thin borders or none at all, but with excellent quality. What started as a trickle of weavers grew into a flood with word spreading of the sisters giving regular work throughout the year above market rates.

Soon, they were roping in entire neighbourhoods of weavers, and young customers from around India, particularly between the age of 18 and 25, began picking up their sarees.

“We are not a brand merely about selling. Behind many of our products, we write stories on our social media handles about why a certain saree is made, the story behind the product and the thought process that went behind it. The biggest motive, however, is to work with a lot of weavers and give them work throughout the year. It’s not just working with them, but including them in the process of designing where they can make suggestions and we sometimes incorporate those changes. It’s not a one-way relationship,” explains Sujata.

“Hence, during the COVID-19 induced lockdown, when many brands weren’t selling, people were still buying from Suta because we kept talking about what we’re doing for weavers in these difficult times. We were onboarding more of them during the pandemic even though we neither had the bandwidth nor cash flow. That’s what sets us apart,” claims Taniya.

Besides their close association with weavers, Suta also seeks to establish a close relationship with the customer as well. Calling their ‘family’ of customers ‘Suta Queens’, their social media posts involve posting photos of the muses in their outfits and accompanied by colourful stories. In these posts, the spotlight is either on the muse (customer) or the story behind the saree.

Of the Weavers, For the Weavers

What stands out most about Suta, however, is their work with weavers in states like Bihar, West Bengal, Uttar Pradesh, Madhya Pradesh, Telangana, Odisha, Kashmir and Tamil Nadu. In the initial years, building trust with these weavers and getting them on board was a massive task.

“But what talks is money! We made sure payment reaches them on time. In the early days of Suta, the moment they would present their sarees to us at their residence or place of work, we would check them and pay up. In certain cases, we even ensured that the wife of a weaver, who has helped him in weaving a particular saree, has a bank account and the work is equally divided. Our appeal to weavers spread through word of mouth,” says Taniya.

The process of onboarding these weavers is quite straightforward.

“Our team meets the weavers. These weavers put forward their samples and our team checks the product for quality and trains them on how we work as a brand. Once finished, the weavers wash them and put Suta stickers on them. Once the final check happens, they are onboarded and then we send designs online via WhatsApp or email. We work with them on a contractual basis. The moment finished sarees reach our hubs (we have two factories in West Bengal, for example), and the QC (quality check) is done, the payment is immediately deposited into the weaver’s bank account irrespective of whether we sell the saree or not,” explains Sujata.

“That’s why weavers work with us for long periods because they always know there is work. Their payment is not based on how we sell their collection unless they keep goofing up. Our QC happens quite fast because we have a big team overseeing it in our factories. Also, our pay structure is slightly higher than the market because our QC is stringent,” adds Taniya.

Learn How to Build Your Own Business From Scratch, From The Suta Sisters

Weavers and artisans are paid on a per-product basis. The compensation is subject to the complexity and intricacy of each product. It also varies depending on whether it is handloom, jacquard loom, power loom and other techniques.

Suta has a full-time contractual agreement with weavers and each weaver’s pay depends on the number of items they’re making, their skill and weaving technique(s). Some artisans just make seasonal products (eg. Batik sarees), wherein the lead time could be much longer than standard sarees. Hence they are given premium pricing over simpler/lesser lead time products.

“We compensate our artisans and weavers adequately depending on their skill set. Also, at Suta, it’s a constant strive to provide 365 days of work to our weavers. About 80% of the weavers and artisans are working on a contractual basis (full-time). This means if the work gets over fast, we create new work for them even when we have tight cash flows. Apart from the 25-35% of the revenue that goes to them per product, we work at improving their livelihood,” claims Sujata.

Sailen Kumar Kundu, who manages a cluster of weavers associated with Begumpur Handloom Cluster Development Society in West Bengal, talks about his dealings with Suta.

“We make cotton sarees. In 2018, we met Suta when they came to find sarees in Begumpur. They found us and enquired about our sarees. They loved our sarees and have been buying consistently till now. If not anything, they buy at least 1800 pieces each year. Suta purchases cotton sarees from us which have 100 /100, 80/100 and 40/60 thread counts,” he says.

Also, when a particular collection from a weaver doesn’t work or there is a colour or design defect in the product, Suta doesn’t send back the inventory. Instead, they either think about presenting the defective products in another collection, employ embellishing techniques like block printing and embroidery or upcycle them.

“Depending on the defect, like a colour error, we take the product, shoot it as a one of a kind product, and we upload it on our website. If it’s a major defect, and the saree doesn’t sell at all, we deduct a small amount so that we can keep the product aside and think about how we can upcycle it. But we never return the saree and let weavers sit with them. Instead, we find ways of upcycling them and sell them in different forms. Most of the yarns we provide, but in certain villages, we don’t control the entire supply chain,” explains Taniya.

Suta even runs this initiative called Suta Earth, where they get old sarees and make bags out of them and ship parcels in them, too. Also, take the example of Khesh sarees, which are made of old sarees that are torn and woven back into them. Many of their single coloured sarees go into Khesh making.

“Whenever there is a defect in the sarees, we put them for upcycling into Khesh sarees. Sometimes weavers stop the loom and go out and when they come back there is a certain line that forms between the saree at the Centre. In a visible area, this line looks quite bad and as a result, customers seek an exchange. To cover that line/demarcation, we do block prints and some other embellishment like embroidery so that the line is hidden,” she says.

In fact, Suta has set up different units to work on the defective sarees.

“If you ask a business consultant or an investor, they would think that what we are doing is foolish. Having said that, we have to be smart to find a solution for products that are defective instead of placing the burden of selling that inventory on the weaver,” argues Sujata.

Their treatment of weavers extended to the COVID-19 pandemic, when they onboarded a lot of new weavers. With no work, many of them reached out to Suta online.

“We wrote an email to Suta sometime around October 2020 talking about how we were finding it difficult to sustain ourselves because of the pandemic. We asked if Suta could help us with some work. Their team visited us and saw our work. They liked it instantly and by November 2020, Suta had started out giving work to us,” says Martin Ghosh, a Kolkata-based artisan.

Marin and his team of artisans make cushions, sarees and curtains for Suta. “We make French knots, Kantha embroidery, bullion, etc. We even get the fabrics from Suta to work on like Batik silk and Mulmul. Last year, we got a lot of work from them. We got around 200-250 pieces of sarees from them to be hand embroidered. Thanks to the work they gave us, 700-800 artisans could earn and sustain themselves. For this, we are forever grateful,” he adds.

Similarly, Jaan Mohammed, a Pashmina weaver from Kashmir, has been working with Suta for the past five years making shawls, stoles, dresses, mufflers and caps for them, also talks about how he survived the pandemic. “During the lockdown, we had less work but Suta supported us during those hard times and we are extremely thankful for that,” he says.

Looking ahead, the target for Suta is onboarding more weavers from different parts of India so that no traditional craft dies. “There is no other target for us except onboarding more weavers. In addition, we want to work completely with natural fibres in the future and expand our reach with more stores and e-commerce avenues like Myntra and Nykaa Fashion. Even though margins may or may not improve, these associations with e-commerce platforms will help us at least move the volume of products and give out more orders for weavers,” says Sujata.

(You can check out on their website here.)

(Edited by Yoshita Rao)

Like this story? Or have something to share? Write to us: [email protected], or connect with us on Facebook and Twitter.

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let’s ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?

This story made me

-

97

-

121

-

89

-

167