Bengaluru Man Replaces Plastic, Cement In Buildings With Sturdy Bamboo Construction

After a string of odd jobs, Parameswaran Krishna Iyer started his own line of bamboo artefacts and furniture with Bamboopecker in Bengaluru. Today, they use bamboo in construction projects for private and government entities pan India as well.

It was a conference that made Parameswaran Krishna Iyer realise his calling in life — to be an advocate of bamboo in India. In 1998, a young Parameswaran was the caretaker of an apartment in Thiruvananthapuram, Kerala, drawing a meagre salary.

One day, a resident businessman requested him to arrange for a few hanging lamps to go with the ‘jungle’ theme of a conference he was organising at the Kovalam beach. But after a quick look, he found that no shop in the city made furniture out of bamboo. He then spotted an ongoing Onam exhibition where one of the stalls was dedicated to bamboo artefacts — all handmade by one skilled craftsman named Stephen.

Parameswaran found the perfect bamboo lamp there and requested Stephen, who belonged to a tribal community that specialises in bamboo crafts, to make 30 of them urgently. Stephen obliged and the lamps were such a hit that there was a fist fight for them among the attendees post the conference. The organiser begged Parameswaran to order 25 more lamps for the attendees who were from all over India.

The incident got Parameswaran thinking. “I searched online on Yahoo for bamboo products and realised that there was a lot of demand, but no supply for bamboo products. That was when I decided to seriously explore the business possibilities in bamboo,” he says. However, funding wasn’t easy and in a few years, Parameswaran had moved to stock markets where he did all kinds of odd jobs till he shifted to Bengaluru and became a relationship manager at a broking firm.

“I kept my dream alive all the while, but it was only in 2009 that I finally found investors in my stock market colleagues. My mentor was Susanth CS, Head of Bamboo Initiative at the National Institute of Design (NID). Inspired by him and another NID professor, I brought Stephen to Bengaluru, rented a small space for the office, set up a small unit made of bamboo and registered the name Bamboopecker,” says the 42-year-old.

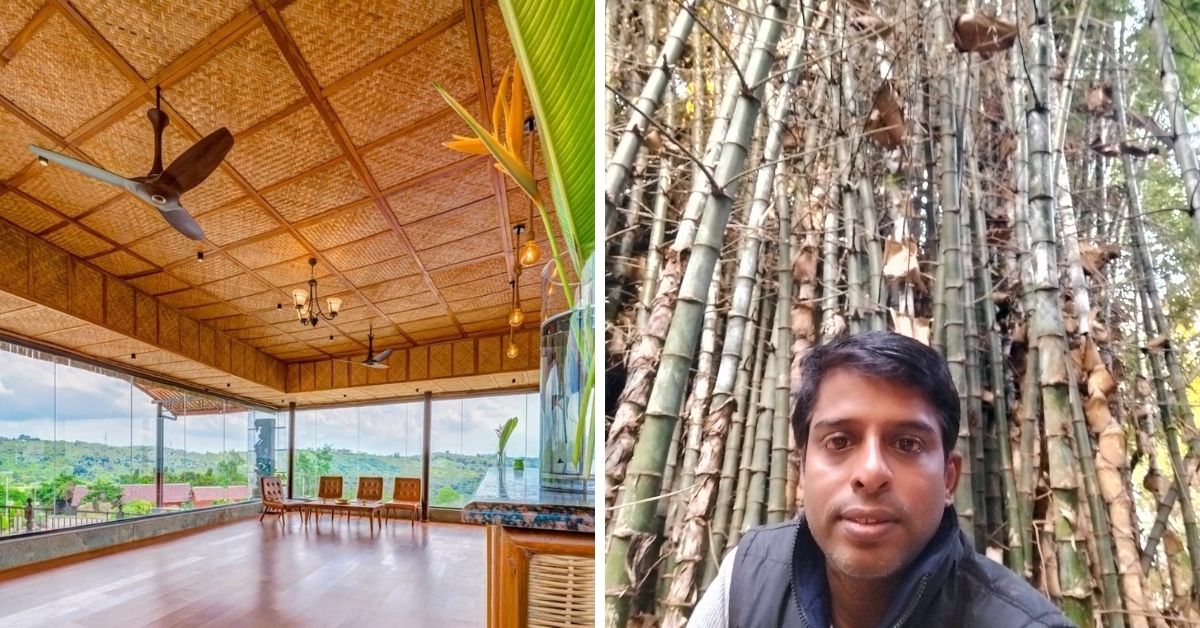

Before long they were flooded with orders, initially only for furniture, interior decor items and artefacts and later for construction projects—resorts, pavilions, farmhouses and more–for private and government entities pan India as well.

Making use of the ‘vegetable steel’

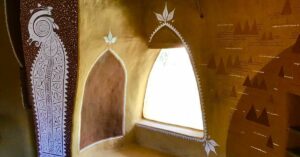

In 2015, they built their own factory in Bengaluru, using only bamboo, mud and other traditional building materials, which later came to be used for demonstration. “People ask me about the profits and the commercial aspects of construction using bamboo. But even today, we are unable to cater to the huge number of orders, all without spending a penny on marketing or ads. I would consider the profits as a bonus or a by-product,” he says, adding that his profit margins of up to 30% are reinvested.

Bamboo, he says, is the most underutilised of natural building materials though it grows abundantly in India. Though it needs to be properly treated, for which Bamboopecker uses Boric Borax (Boron) solution, a non-toxic mild salt to neutralise sugar components and avoid pests.

“The tensile strength of bamboo is the same as that of mild steel owing to its fibrous nature, which is why it’s called vegetable steel. The key lies in harvesting the poles at the right time and employing the correct treatment methods. It also depends on planting the right species at the right places to optimise their growth. Once treated, bamboo will stay intact for 20 years or more,” he says.

He cites an instance where they were approached to replace the bamboo poles of a palanquin at the Sree Padmanabhaswamy Temple in Kerala, only to find that the existing one had been in use for the past 150 years.

For the same reason, bamboo—the cheaper alternative—can replace steel in pillars, beams, ceilings and rafters, especially in construction in ecologically sensitive areas. “Bamboo construction suits earthquake-prone areas as the poles neither break like concrete nor bend like metal. They retract to the original shape after the impact. I have also often explored the possibility of low-cost housing projects with bamboo for flood-prone areas, since the entire house will float in the event of a natural calamity, causing minimum damage, if tethered properly,” he says.

As of now, bamboo huts and structures are mostly used for temporary structures or resorts but one of Parameswaran’s long term goals is to advocate its use for permanent structures and replace plastic in furniture and décor.

The shoots can regrow quickly, but large scale plantations are still absent in India. “The bamboo market is still an unorganised sector. The supply to demand ratio is still 1:10. We are still forced to source the poles from different parts of India and what we get is often not what we want or the poles are damaged along the way,” Parameswaran says, adding, “The labour charges are what makes bamboo artefacts and construction expensive. We aim to reduce labour costs with mechanisation and increase production so that the product costs come down. I don’t want to stay confined to a premium market. I want to make bamboo products affordable to the common man.”

Bamboopecker’s handmade products like dining chairs, foldable deck chairs, benches, stools and rocking chairs, range from Rs 1,500 up to Rs 25,000. Construction costs, depending on the labour and materials, ranging from Rs 50,000 to Rs 50 lakhs.

Transportation charges for the raw materials also hike up the product costs so his bigger aim is to set up manufacturing units in different parts of India and create rural employment. “We are already on our way to set up a unit in Arunachal Pradesh from where we source most of our bamboo. We plan to get the poles treated right at the source.”

Last year, Bamboopecker took up a 1.5-acre property in Hoskote, near Bengaluru, where they used natural materials to construct a bigger factory. With business partner Suman Roddam and team, Parameswaran now holds workshops and training sessions on bamboo at the property, often at the request of various environmental agencies. One of their latest projects is a building for a Bamboo Research and Training Centre of the Maharashtra Government. They also have a bamboo grove consisting of 45 different varieties.

Amidst it all, Stephen, the original craftsman, had to return to Kerala, as the cool climate of Bengaluru did not agree with him.

“India is still in nascent stages when it comes to the proper marketing of bamboo. We need to innovate, modernise products and bring bamboo to the mainstream. But during these COVID times, I would request everyone to plant at least one bamboo sapling near their houses,” says Parameswaran, adding, “Bamboo produces 35 per cent more oxygen than any other plant, a fact which has been scientifically proven. Let’s begin there.”

For more information on Bamboopecker products, click here.

(Edited by Yoshita Rao)

If you found our stories insightful, informative, or even just enjoyable, we invite you to consider making a voluntary payment to support the work we do at The Better India. Your contribution helps us continue producing quality content that educates, inspires, and drives positive change.

Choose one of the payment options below for your contribution-

By paying for the stories you value, you directly contribute to sustaining our efforts focused on making a difference in the world. Together, let's ensure that impactful stories continue to be told and shared, enriching lives and communities alike.

Thank you for your support. Here are some frequently asked questions you might find helpful to know why you are contributing?

This story made me

-

97

-

121

-

89

-

167