Tamil Nadu Man Invents Cashmere-like, Vegan Wool From Wild Dry-land Shrubs

Once the fibre was obtained, the plant components that remains is used to make a liquid extract, Arka. This is used by farmers as bio-fertliser and for pest control. #innovation

Growing up, we all learned about natural textiles and those that are synthetic. We learned that those that are naturally derived are better for the environment as they do not leave any trace behind and decompose with ease, unlike synthetic fibres. But what about wool?

Although wool is a natural fibre derived from sheep, experts and animal rights activists have raised several concerns across the globe. They highlight unfair conditions in which the sheep are bred and reared for the wool. Sheep also have to go through a process called ‘mulesing,’ in which strips of their skin are cut to prevent ‘Flystrike’.

So, this really makes one think if there is a way to obtain natural wool without infringing on the rights of an animal.

Luckily, one man found the solution.

Meet Gowri Shankar, an entrepreneur based in a village named Kuilapalayam in Tamil Nadu (near Auroville) has found a unique solution. The 34-year-old is the founder of ‘Faborg,’ a company that makes vegan wool derived from Calotropis, a wild flowering shrub which is found in dryland areas, and is commonly known as milkweed.

Calotropis, The Wonder Shrub

After working in the fashion sector for several years, Shankar decided to look at ways in which sustainable fabric could be derived from plants like hemp and banana. It was with this idea in mind that he founded Fabrog in 2015, while also taking on freelance assignments for other merchandising companies.

It was during this phase in 2017 when he first got the idea of making fabric derived from this unique shrub.

“I was just casually staring outside the window one afternoon in April and I noticed something. There were about 10 to 15 sunbirds surrounding this bush and they were making a nest using this particular fibre. It really got me thinking if this is natural fibre could be transformed into a textile,” recalls Shankar.

After months of research and experiments, Faborg has launched an alternative for wool fabrics, called ‘Weganool’. Every process involved in the extraction of this fibre is sustainable including dyeing, where plant-based natural colors are used.

To further make the entire process zero-waste, Shankar read up on the plant’s many properties. He found that once the fibre was obtained, the plant components that remained could be used to make a liquid extract.

“In the olden days, the plant extract was used for its insect repelling qualities. It also has antifungal and antibacterial properties. We also found that this shrub naturally grew in soil that was stripped off nutrients and needed less water to survive. Moreover, we also found that over time, it enriched the soil in which it grew and helped plants growing near it flourish,” notes Shankar.

Thus, this research led to the launch of ‘Arka’ in 2018, a bio-fertiliser and pest repellant that could be used by farmers to practice chemical-free agriculture.

Arka also had several other benefits. The plant extract made by mixing herbs like neem, eucalyptus and lemongrass also serves as a natural mosquito repellent that is being used by the service industry.

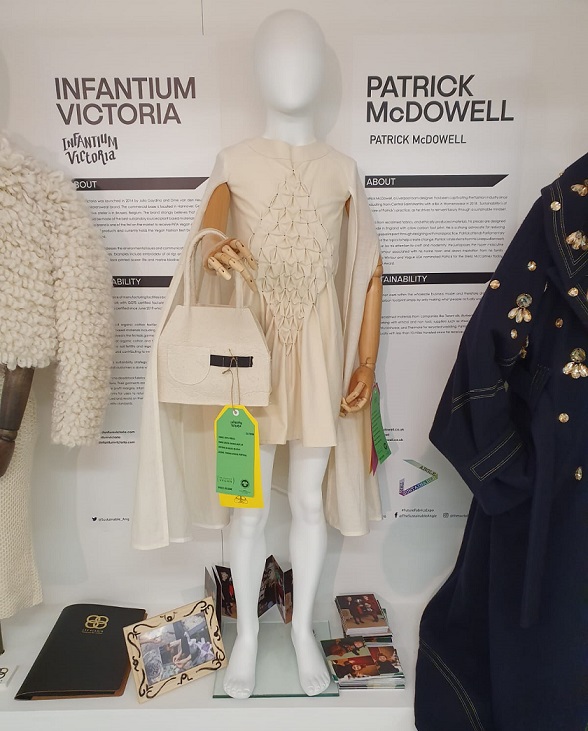

Now, Faborg manufactures about 150 kgs of yarn per month which is being used by brands and sustainable design brands like Infantium Victoria, a German fashion label that makes children’s clothing. Moreover, Shankar mentions that they have gotten inquiries from designer labels like Gucci, Louis Vuitton and Alexander McQueen. Most of these brands have liked the fabric’s cashmere-like texture which is perfect for making woolens.

Additionally, about 22 farmers who collectively have a farming land of 130 acres have used Arka for nourishing their plants as well as naturally keeping pesky pests away. This solution is also made available at a 70 per cent cheaper subsidised rate so that they can buy it with ease.

Arka is also being used as a mosquito repellant by about 30 cafes, hotels and restaurants.

In conversation with The Better India (TBI), Shankar shares Faborg’s interesting journey and how he discovered the multiple benefits of a wasteland shrub.

Born Around Textiles

To say the knowledge of textiles runs in Shankar’s blood, would be an understatement. Born to a family of traditional weavers from the Devanga Community in Tamil Nadu’s Tiruvannamalai district, he grew up in a world where fabrics were handwoven with hard work. He was in high school when he decided to pursue vocational training in textiles.

“I would help out my parents in handling the fabric, the way it was woven and warped. I was surrounded by handlooms and hence, it was a kind of knowledge that I just couldn’t have missed out on,” recalls Shankar now.

Later, after developing an interest in the Hostel and tourism sector, he decided to pursue a BSc in Home Science and Hotel Management from the EMPEE Institute of Management and Catering Technology in Chennai. He then followed this up by a Master’s in Tourism from the Annamalai University in Chidambaram, passing out in 2017.

He then decided to pursue a career as a bartender in a hotel for over one and a half years. After this, he joined a fashion house in Chennai as a merchandising manager working with them until 2012. Here, he learned about the trends in the fashion industry, adding it to his pre-existing repository of knowledge on textiles.

Having worked in the industry for so long, he knew about the excesses of the fashion industry and how polluting the production processes can be from obtaining the fibres to dyeing it. This is what urged him to adopt an alternative approach to textiles where he began experimenting with natural plant-derived fibres.

“I found that although the hemp and banana fibres were quite nice, there wasn’t any special value to them. If we went into manufacturing and sold this, there would be nothing that would set it apart from other fabrics available in the market,” explains Shankar.

After making that observation involving the hummingbirds, their nests and the Calotropis plant, Shankar immersed himself into researching and learning more about the fibres. He learned that although the plant had several benefits, all the research was isolated and not consolidated in the right manner that could truly highlight the value that this plant possessed.

“There is a difference in a way how one needs to handle this plant. Unlike in the case of hemp or linen, the fibres from the Calotropis plant need to be processed in a way that they retain their strength,” informs Shankar. The fibres are obtained from two different parts of the pant, from the pods and from the stem.

After much research, he found that blending 30 per cent of this particular fibre along with 70 per cent cotton fibres helped them achieve a fabric that was perfect for woolen wear. And, the best part here was that no animals were involved in the entire process.

Once they made a breakthrough with the Calotropis fibres, he began looking at different components of the plant and how to utilise them. After finding that a lot of liquid and plant components remained after the extraction of fibres, he decided to make the ‘Arka’ plant extract for its many benefits.

“The plant is rich in micro and macronutrients and the alkaloids present in the extract helps in plant cell division. It also improves the quality of the soil and naturally keeps pests away without even killing them,” explains Shankar.

Going about the Operations

The operations for Faborg are carried out at a 2000 sq feet unit in Pondicherry. Currently, they have about five people working here while weaving is carried out by weaver clusters in Karur, Tirupur among other places.

At the unit in Pondicherry, the fibre is extracted and the dyeing of the yarn also takes place in Tirupur at Natural Dye House. Shankar points out that they only use natural dyes derived from plants like Kaddukai and are used for yellow dyes while pomegranates are used for red dyes. The dyeing services are also made available for other clothing brands who naturally want to dye their fabrics.

“To separate the fibers from the plant, it takes a lot of time and includes many steps. Once the plant is harvested, the stem is separated from the plant. The fibrous bit inside the stem is extracted and is boiled in water. After this, it is sun-bleached and then turned into yarn,” informs Shankar.

This fascinating process and the concept of vegan wool has attracted a lot of attention. Several brands have also started sourcing this fabric after learning about it. Take Julia Gaydina for example who is the co-founder of Germany based organic and vegan children’s clothing brand Infantium Victoria. She was scrolling through Instagram when she first learned about Fabrog and her curiosity led her to check the website in 2019.

Later, when she and the co-founder were planning a trip to India in fall 2019, she wanted to visit Faborg in person to learn about their operations.

“Upon our first visit, we took a few meters of the fabric that was available to create a few products for our collection. We decided to create some basic garments that would demonstrate the beauty and the flow of the Weganool. Our first garments made from this plant-based wool alternative include a hoodie, baby jacket, and a cape gown. The response from clients is overwhelming!” informs Julia.

Julia informs that the customers were really happy to touch the cashmere-like textile, which was cruelty-free and did not involve any chemicals.

“The holistic approach to creating new fabrics, improving the lives of the community, and fertility of the soil is why we love their philosophy. I think the project of this is a project that will make a huge difference. What Weganool is not just a beautiful fabric, it’s a massive opportunity for textile and agriculture industries,” she says enthusiastically.

Additionally, there are farmers in the region who have used the plant extract, Arka, for their farming practices. Rachana Rao is one such farmer based out of Tindivanam, a town located about 40 mins away from Pondicherry.

Two years ago, the 29-year-old decided to pursue farming and began her agriculture practice on 25 acre land, which she says is basically a food forest with several trees. Out of this, about six acres of land is cultivated where on the one hand she is growing fruit trees like mango, jamun and cheekus. While on about two acres of land, she’s growing different vegetables, along with rice, peanuts, millets and lentils.

“I practice natural farming and Arka is something that I have been using for over a year. To increase the microbes in the soil as well as for pest control, this is really good as it does the job naturally. I spray it on my crops and trees once every two weeks for best results,” she says.

Overcoming Obstacles and Looking Ahead

Looking back on his journey, Shankar says that the biggest challenge for him so far had been coming up with Weganool in the first place.

“Keeping the process completely chemical-free was a huge challenge and once we cracked that, the other aspects of the operations just became easier. Another challenge was finding natural due but we have experts in our team who are adept with chemistry and have PhDs in natural dyes. Other than that, finding a place to carry out the operations and now scaling our business is a constant challenge,” he says.

As a bootstrapped venture, Shankar says that he is open to collaborations with like-minded individuals and businesses in the industry. He believes that this will help the products reach far and wide.

Also, from his own learning curve, he has a few pointers for entrepreneurs like himself.

“When an entrepreneur starts his venture, it is important to ask why and how questions so that it’s clear what they are doing and want to achieve. Step up and keep working towards your goal, until you have a breakthrough. Keep setting new goals for yourself. Spend more time reading, researching and learning,” he says.

So, what does the future look like for Faborg?

Shankar informs that now some big plans are underway. They not only want to scale their own operations but they are also looking at cultivating the Calotropis plant themselves along with other crops. This would ensure there is a constant supply of raw material for their operations while growing this plant with other crops can help improve the fertility of the soil.

“I want to have a processing unit for Faborg in every 100 km of India wherever the plant is growing. I hope to create a working model for farmers so that they can become self-sufficient. To this network, I want the farmers to realize the real potential of this shrub and how it can improve their incomes,” he says signing off.

Rapid-fire:

*An entrepreneur you admire.

Ans: Rajarajan, Co-founder of Natural Dye House

*New tech that can transform the future of small businesses

Ans: Any technology that is efficient and can automate different processes

*One value that can help small businesses thrive

Ans: Willingness to hustle

* Any app/software that helps you manage your work

Ans: WhatsApp as most of the engagement is through this platform

*Your favourite book

Ans: Bharathiyar Kavithaigal

*In my free time, I ____…

Ans: play with my dog and work in my garden

* Before this interview, I was ____…

Ans: eating vegan pizza

* A message for your past self about small businesses

Ans: There are going to be ups and downs but you have to enjoy the ride

*Best advice you ever got is ____…

Ans: never to look down upon anyone.

(Edited by Gayatri Mishra)

This story made me

- 97

- 121

- 89

- 167

Tell Us More

We bring stories straight from the heart of India, to inspire millions and create a wave of impact. Our positive movement is growing bigger everyday, and we would love for you to join it.

Please contribute whatever you can, every little penny helps our team in bringing you more stories that support dreams and spread hope.