In what is potentially a game-changer for the environment, Carbon Craft Design, a Mumbai-based design and material startup is harnessing air pollution to make carbon tiles.

Yes, you heard that right!

The startup, which was officially founded in January 2019, is working in collaboration with Air-Ink, a Boston-based startup that is processing the air pollutants and providing them with the soot to use in their innovation.

This innovation is relevant because it is a small step towards introducing an alternative in the construction industry that accounts for almost 25 to 40 per cent of the world’s carbon emissions.

“Each carbon tile is equivalent to cleaning 30,000 litres of air! Moreover, these tiles consume only one-fifth of the energy required to manufacture vitrified tiles. This means, instead of burning the tiles to come up with the finished product, we use a hydraulic press that helps us in manufacturing these tiles,” says Tejas Sidnal, the founder of Carbon Craft Design.

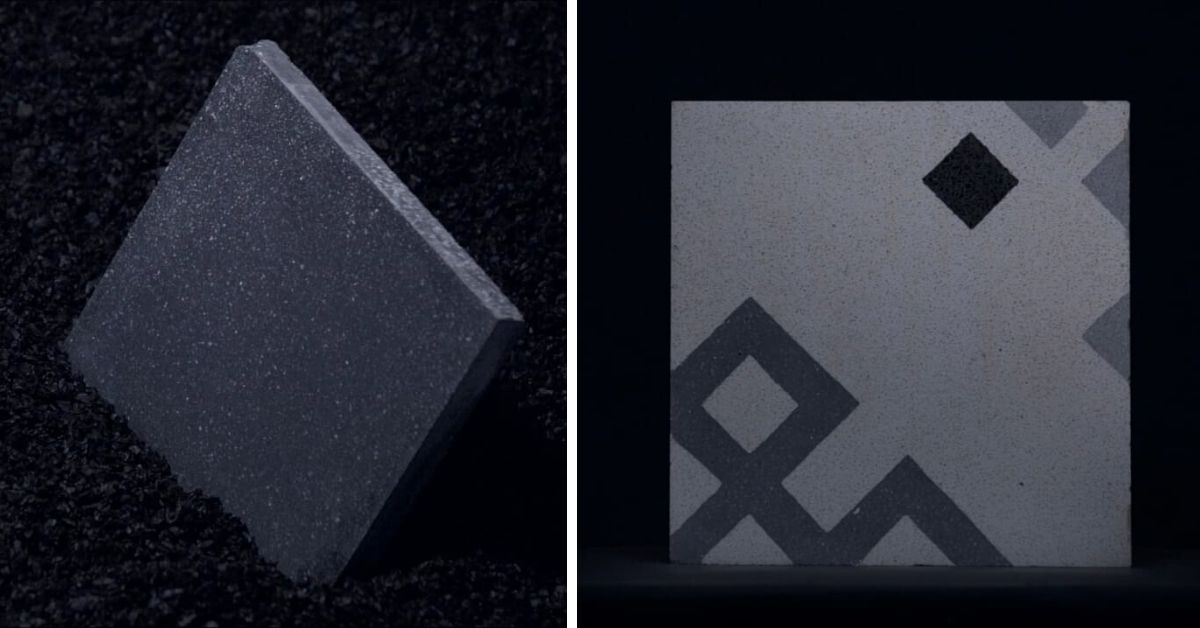

All the heavy metals and harmful components are removed from the soot, following which, traditional craftspeople in Tamil Nadu and Gujarat handcraft the tiles that come in six monochromatic shades ranging from black, four shades of grey, and white.

These tiles were launched in the market in January this year, and the startup already has three orders and will be supplying about 4000 tiles in total!

An architect, innovator and entrepreneur

Tejas has a Bachelor’s degree in Architecture from the University of Mumbai. As a student, he became deeply interested in biomimicry, which is a method for creating solutions to human challenges by emulating designs and ideas found in nature, and wondered if it could be employed to design sustainable and environment-friendly structures.

“I stumbled upon the concept of biomimicry at a design competition in my third year of college. Since then, I began reading up on it, and during my thesis, I focussed on the subject and turned towards nature and how we can design around it,” says the 32-year-old.

Fresh out of college, he joined Ratan J Batliboi Architects, a Mumbai based architectural firm. While he was working as a junior architect, he started looking for courses that could suit his interests of biomimicry and nature focussed technical solutions.

However, he couldn’t find many courses that met his requirements.

Finally, he secured a scholarship and got through a Master’s programme of his choice at the Architectural Association (AA), School of Architecture in London. Here, he graduated with a degree in Emergent Technologies and Design in 2013.

He stayed in the UK for a bit and became closely involved with AA’s annual architectural visiting school workshops that focussed on biomimicry, computational tools, and material systems.

In May 2014, he shifted base to China where he worked for a year until June 2015 and returned to Mumbai to start providing freelance consultancy services. He was also engaged in the annual AA Breathe visiting school workshops and became the director.

In 2016, Tejas watched a video on Air-Ink and their innovation of being able to process air pollution into soot. This got him wondering if he could use his knowledge of architectural design, material systems, and biomimicry to produce a building component using it.

He met with the founders and got some samples for them to start testing it. Initially, he wanted to start experimenting with making bricks. This went on for a bit, and meanwhile, he also founded a design consultancy and architectural interior research firm in July 2018 called, ‘Median’ with his college buddy Suraj Suthar.

At one point, his experimentations to produce the carbon bricks were successful, but that idea did not see any execution.

“Although we could develop the bricks, the process of making them was expensive and time-consuming. It was not very conducive for the market,” informs Tejas.

In December 2018, he was coordinating another AA visiting school, and here the theme was air pollution and architecture. Architecture students and practitioners came from all over the world, which led to a great deal of exchange of information. After this, Tejas realised that for a product to be accepted in the market, the product should have a design value that is lacking in the bricks.

Thus, he took this idea forward and found Carbon Craft Design in January 2019. He hired a researcher and technology head to help him come up with the tile, and after countless experiments and time in the lab, they developed the carbon tile in May 2019.

Making the perfect carbon-conscious tile

Once the team at Carbon Craft Design came up with the perfect prototype, they identified traditional handcrafted cement tile producers in Tamil Nadu and Gujarat, to manufacture the tiles on a large scale,

The soot is infused with materials like marble chips, marble powder, cement along with a proprietary binder. The tiles come in three sizes—8″x8″, 10″x10″, and 12″x12″.

These carbon tiles are handcrafted, produced consciously, and cost Rs. 190 per sq of the tile used. In comparison, vitrified tiles which are conventionally used, take five times more energy to produce and cost anywhere between Rs 50 and can go up to Rs 1000 per sq feet.

Customers who are willing to buy the carbon tile can also get it customised as per their design requirements except they have to pay extra for the stencil that needs to be made especially for this purpose.

The stencil can cost anywhere between Rs. 5000 and 15,000. In case they want to avoid this cost, they can go for the 15 designs that the startup also has in their portfolio.

Tejas is extremely grateful to Air-Ink and their collaboration, which allows them access to processed carbon soot—which is the basis of the work they do.

“I realised very early on that we cannot manage two tasks at hand. One being, the collection of air pollution and it’s processing. We neither have the device, not the resources to process it. If we had to invest and spend time doing that, perhaps we would’ve never been able to come up with the tile so quickly. Hence, this association with the startup is instrumental for us,” he says.

When it came to reaching out to customers, it wasn’t too much of a challenge for Tejas as he already had a good rapport with several people in the architecture and construction sector.

One such contact is architect Sachin Patil who runs his own independent architectural and interior design firm and came across the carbon tiles on Facebook.

“A client approached me to make a sustainable resort in Revdanda in Alibaug. When I shared the idea of using these tiles with them, they immediately hopped on board. So, we are installing them in an area measuring about 5,400 sq feet,” he shares.

Overcoming challenges and looking forward

Having come up with a unique innovation in the sphere of material design and architecture is commendable. However, Tejas has dealt with plenty of challenges in this journey.

“To begin with, standardising the colour of the tiles is difficult to achieve because the pollution at every site won’t be the same. For example, the emission will be different for each of the fuels, which means that there will be a difference in the components as well. Consequently, when it is processed, there is a variation in the colour of the powder,” he shares.

But, since these tiles are handcrafted and they are working with different monochromatic shades, they are dealing with this challenge without putting too much pressure on themselves.

Another challenge that Tejas speaks about is that a lot of people do not take environmental issues too seriously. This is sometimes a hindrance to them when it comes to explaining the idea and value behind their innovation.

“We spend a lot of time explaining our solutions and how this is a viable alternative. Since consciousness is not at it’s best at the moment, we are currently functional in a market space that is not very huge or rather conducive,” he says.

However, despite these few setbacks, big companies like JSW and Larsen & Toubro are in talks with the startup.

“They want us to collect carbon emissions from their construction sites and to manufacture tiles for them. This way, they are trying to manage the emissions they are responsible for. Eventually, we want to scale in this model where we can help large companies do that as environmental concerns are growing at large,” explains Tejas.

There are several plans that Carbon Craft Design has for the future. To begin with, they are working on establishing networks with distribution channels abroad in places like Miami, Sri Lanka, Dubai, among other places.

As these tiles can only be used indoors, Tejas eventually hopes to start manufacturing outdoor tiles as well, along with other architectural products like light fixtures, home accessories, furniture, among others.

He also wants to make this innovation even more affordable, but that can only happen if the demand for these kinds of products grows, thus expanding the scope of the current market.

“Our ultimate vision is to be able to construct a carbon-conscious building which is made using each component derived from processing air pollutants,” says Tejas signing off.

Also Read: Bamboo & 90% Recycled Waste: Kerala Architect Builds Green Home in 4 Months!

(Edited by Gayatri Mishra)

Like this story? Or have something to share?

Write to us: contact@thebetterindia.com

Connect with us on Facebook and Twitter.

We bring stories straight from the heart of India, to inspire millions and create a wave of impact. Our positive movement is growing bigger everyday, and we would love for you to join it.

Please contribute whatever you can, every little penny helps our team in bringing you more stories that support dreams and spread hope.